Type: palm oil fractionation based on melting points

Processing materials: palm oil

Capacity: 10-500T/D

Main equipment: crystal pot, screw – water chillers, membrane filter press

Application: new

Type: palm oil fractionation based on melting points

Processing materials: palm oil

Capacity: 10-500T/D

The main equipment: crystal pot, screw – water coolers, membrane filter press

Application: new type of oil fractionation technology applicable for palm oil, cottonseed oil, peanut oil, fish oil, chicken oil, algae oil , linseed oil

Palm oil fractionation technology adopts advanced palm oil processing technology of controlled cooling, crystallization, filtration and separation technology, obtaining palm oil with melting points, like 33℃, 24℃, 18℃, 14℃, 12℃, 10℃, 8℃, etc. This selected palm oil fractionation machine with fully computerized automation is selected by low investment , liquid oil yield, high purity of solid fat, high profits, etc.

Principle of operation of palm oil fractionation technology:

Palm oil is composed of triglycerides with a variety of melting points, which translates into different palm oil melting point ranges. Palm oil is divided into a solid part and a liquid part through the use of different solder points and different solutions of different oil component triglycerides.

Based on the difference in properties of triglycerides, it creates related crystallization conditions in order to crystallize and separate from the original solution with high purity. This process is called palm oil fractionation.

The liquid fraction (olein) is widely used as a cooking liquid for palm oil in tropical climates. Liquid palm oil is competitively priced with more expensive peanut, corn and sunflower oils.

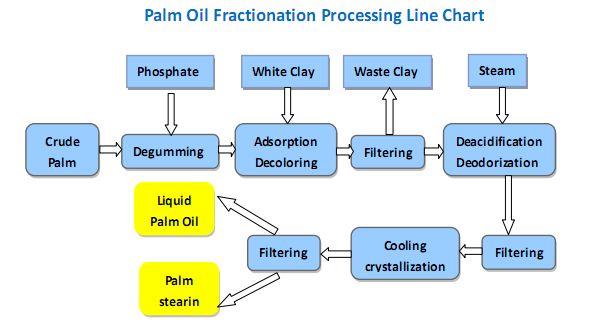

Palm oil fractionation processing line diagram: