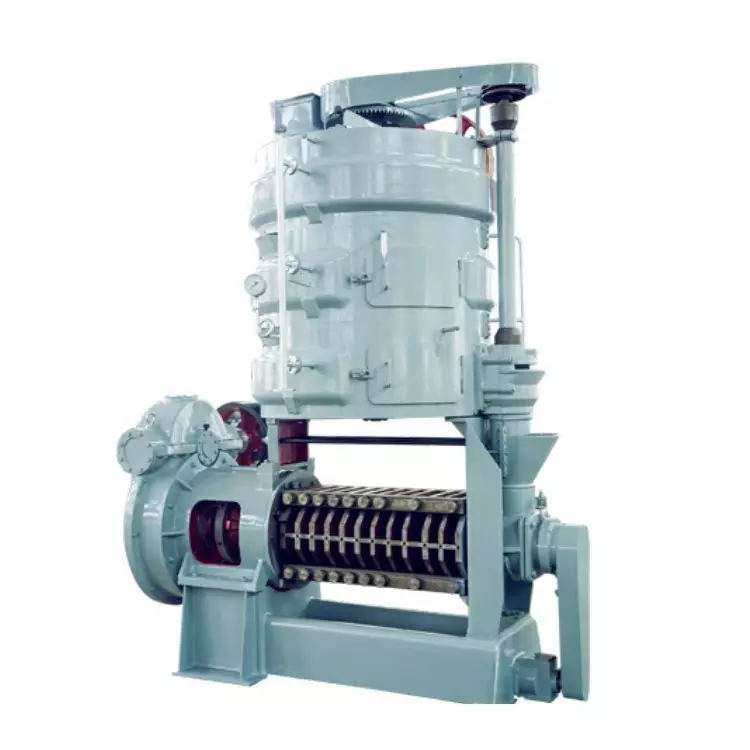

oil press machine, which is also called oil expeller, oil extraction machine or oil mill, It can be used for various raw materials, such as soybeans, peanuts, cotton seeds, rape seeds, sesame seeds, sunflower seeds, canola seeds, coconut seeds, tea seeds, palm kernel, rice bran, corn germ, olive, coconut/copra and so on.

|

Model

|

Capacity

|

Power

|

Size

|

N.W(Net weight)

|

|

ZX18(200A-3)

|

10t/d

|

18.5kw

|

2900*1850*3240mm

|

5000kg

|

|

ZY24(200A-3) pre-press

|

40-50t/d

|

30kw

|

2900*1850*3640mm

|

5500kg

|

|

ZY24A

|

60-80t/d

|

30+5.5+3kw

|

2900*1850*3950mm

|

5500kg

|

|

ZX28

|

40-60t/d

|

55+11+4kw

|

3740*1920*3843mm

|

9160kg

|

|

ZY28

|

120-150t/d

|

75+11+5.5kw

|

3740*1920*2843mm

|

9160kg

|

|

ZX32

|

90-100t/d

|

90+11+5.5kw

|

4100*2270*3850mm

|

11000kg

|

|

ZY32

|

220-260t/d

|

110+11+5.5kw

|

4100*2270*3850mm

|

11000kg

|

Complete oil pressing plant:

Complete oil pressing plant is used to press various oil seeds(sunflower, cotton seed, peanut, soybean, rice bran, corn germ, mustard, rapeseed, coconut,olive, sesame, castor bean, palm kernel and so on. It is used in large oil factory, the plant mainly include cleaning, crushing, flaking, cooking, prepressing/pressing, filter process

1. cleaning process: Use vibration cleaning sieve ,destoner,and magnetic selector to get better cleaning effect.And This step is mainly to clean the big impurities ,like the stone, big dust , iron etc. 2. Crushing Process: This Process is mainly to crush the oil seeds into small pieces , Like the peanut is big ,it is not easy to press, we use crusher machine to crush peanut into 5-6 pieces 3.Flaking Process : After crushing, we need to flake the crushed oil seeds , Like sunflower, which make the cell wall of sunflower broken . And we flake the sunflower to 0.55 mm thickness .Then it is useful for the oil extracting..

4.Cooking Process: After the flaker,we need to cook the flaked raw material , control and adjust the moisture and temperature, make raw material reach the best condition for pressing.

>5.Pre-pressing process/ Pressing process: After above all pretreatment, the raw material reach the best condition for prepressing/pressing, We put raw material into pre-press or press machine according to your requirement. For high oil content oil seeds, such as peanut, sunflower, we put raw material into pre-press, keep higher oil residue in the cake, the cake is sent to another solvent extraction plant, to get oil from oil cake. For low oil content oil seeds, we can use press machine to press raw material, finally about 6% oil residue in the cake. 6. Oil filter process: After pressing, the crude oil will be sent to filter to filter impurities in the oil,then crude oil is stored in oil tank or further oil refinery process.

Cases

FAQ

Pre-Sales: Act as a good adviser and assistant of clients,enable them to get rich and competitive from the returns of their investment. 1.Communicate with customer,confirm requirement 2.Design and manufacture products according to clients requirements. 3.Sign contract 4.Shipping machines