We are an expert in designing vegetable oil production line, including sunflower oil production line, soybean oil production line, peanut oil production line, palm oil production line, and more. With years of experience in exporting, designing, and installation of both small and large oil production line across the world. We offer professionally customized vegetable oil production line of 5TPD to 500TPD capacities at the most competitive prices.

MORE READ:Factory price for sale soybean olive oil press machine

We produce quality vegetable oil production line, we manufacture quality cooking oil making machine for both crude and refined of sunflower oil, corn oil, soybean oil, palm oil, rapeseed oil, peanut oil, cottonseed oil, mustard oil and more. We also do importation and exportation of vegetable oil production machine and seed pretreatment machine for oil processing and refinery. We sell at CIF and FOB competitive prices.

Generally, sunflower oil production line does the following manufacturing processes: cleaning of the seeds, grinding of the seeds, pressing and extracting crude oil from these seeds, and then further refining the oil obtained before packaging.

The harvested oil-bearing seeds are passed over magnets to remove any metal traces, and other impurities are being got rid of by cleaning sieve and destoners. Then the outer covering (hulls) of the seeds are removed to obtain pure seeds.

The de-hulled seeds are ground into coarse meal to provide a larger surface area to be pressed. Hammer mills or grooved rollers are used to crush the coarse meal into uniform fine particles. Then the meal is heated to enable oil extraction, though impurities are released with oil during this process and such impurities should be removed before the oil is declared edible.

The heated meal is fed into a screw oil press which progressively, at the same time, the oil is squeezed out through the slots in the barrel and recovered.

Oil refining involves removal of the bitterness, color, and odor. First, the oil is heated at temperatures between 40 0C and 85 0C. Then it’s mixed with an alkaline substance like sodium carbonate or sodium hydroxide. The oils are degummed by treating them with heated water at temperatures between 85 0C and 95 0C or with acidified water. This precipitates out most of the gums usually phosphatides. Then centrifugation is done to remove the dregs.

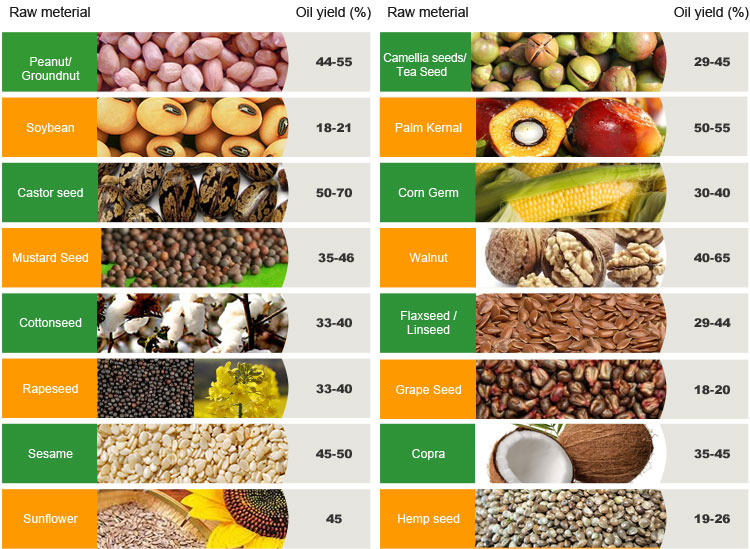

Raw materials for vegetable oil produciton line

Our factory price vegetable oil production line is suitable for various oil-bearing seeds, including castor bean, mustard seed, cottonseed, sunflower seed, copra, hemp seed, corn germ, and more. If you are interested in our oil production line for different plants, please contact us for more details!

We meet the demands of virtually every application in the vegetable oil processing industries. With premium quality oil mill machinery, oil extraction machines and professional oil processing systems & oil refining technologies in the field of vegetable oil extraction and refineries, you can depend on our equipment and expertise to help you hulling, crushing, conditioning, flaking, cooking, extruding, expelling, extracting, degumming, neutralizing,dewaxing/fractionation.

|

Model |

Capacity |

Oil in cake |

Power |

Overall dimensions(L×W×H) |

N.W. |

|

ZY24A |

60-80 t/d |

12-18 % |

30+5.5+3.0 kw |

2900×1850×3640 mm |

5500 kg |

|

ZX24A |

15-20 t/d |

7-9 % |

30+5.5+3.0 kw |

2900×1850×3640 mm |

5500 kg |

|

ZY28 |

120-150 t/d |

16-20 % |

75+11+4.0 kw |

3740×1920×3843 mm |

9160 kg |

|

ZX28 |

40-60 t/d |

7-9 % |

55+11+4.0 kw |

3740×1920×3843 mm |

9160 kg |

|

ZY32 |

220-260 t/d |

16-20 % |

110+11+5.5 kw |

4100×2270×3850 mm |

11000 kg |

|

ZX32 |

90-100 t/d |

8-10 % |

90+11+5.5 kw |

4100×2270×3850 mm |

11000 kg |

Strong manufacturing ability

♦ We have a professional service staff, and timely communication with the user, so that each machine is a “hen”lay eggs to make money.

♦ Nearly one century’s history of manufacturing machinery,has a very valuable experience in manufacturing and technology services. Ensure every machine perfect.

♦ We are the leading manufacturer and supplier of small oil press machine. Through years of development, our products has been rated as the best and reliable oil making equipment in the world.

♦ Therefore, we have been awarded various quality authentication from government institutes and alibaba. What’s more, our good service is also well received by customers around the world.

Packing and delivery

1.The normal package is wooden box. If export to european countries,the wooden box will be fumigated.Or as customers required.

2.Port: Qingdao,Shanghai,Tianjing.

3.Lead time: Within 5-25 working days after payment confirming.