Our Machinery is a reliable manufacturer of vegetable oil machine including screw oil press/expeller, hydraulic cold expeller press, mechanical oil pressing machine, solvent oil extraction machine, automatic mustard oil machine, soybean oil machine, groundnut oil machine and also customized cooking oil production line and crude oil refinery equipment. Over 10 years of experience in equipment manufacturing and project construction has proved our strong ability and great product quality.

↘Main Equipment for Vegetable Oil Manufacturing Plant

⚙️Oil Expeller Machine (Oil Squeezer): Includes traditional screw oil expeller and cold pressed hydraulic oil press machine. It can be widely applied to make oil from various oilseeds such as soybean, peanut, sunflower seeds, cottonseeds, sesame, rapeseed, linseed, neem, moringa seeds, pumpkin seed, flaxseed, grape seed, etc. (Capacity Range: 0.8ton~20tons/day small oil mill plant, medium-sized oil processing plant)

⚙️ Oil Refinery Plant: The edible oil refining machine is to remove all kinds of impurities, and make the least damage to the neutral oil and natural antioxidants (tocopherol), so as to produce high quality oil produces. According to the refining scale, it is divided into 1-10ton/day Batch Type Small/Mini Oil Refinery Plant, 10-50 ton/day Semi-Continuous type Crude Oil Refinery Plant and 30-100T Continuous Vegetable Oil Refinery Plant.

⚙️ Complete Oil Mill Plant: Offer customized both 1-20ton/day small oil production plant and 20-500ton/day cooking oil manufacturing plant. All our projects are designed based on different oilseed, capacity, and your specific situation and requirements. The main types of vegetable oil processing process includes oil squeezing/pressing, solvent extraction, pre-pressing & solvent extraction, oil refining, oil purification/clarification, oil fractionation.

|

Model

|

Power(KW)

|

Capacity(KG/H)

|

Dimension(MM)

|

Weight(KG)

|

|

6YL-30

|

1.5 kw

|

15 kg/h

|

900*900*1100 mm

|

156 kg

|

|

6YL-60

|

2.2 kw

|

30 kg/h

|

600*650*880 mm

|

210 kg

|

|

6YL-70

|

4 kw

|

30 kg/h

|

1000*1000*1250 mm

|

256 kg

|

|

6YL-80A

|

5.5+0.75 kw

|

100 kg/h

|

1890*1160*1790 mm

|

700 kg

|

|

6YL-95A

|

7.5+1.5 kw

|

150-200 kg/h

|

2100*1200*1890 mm

|

900 kg

|

|

6YL-100A

|

7.5+1.1 kw

|

200 kg/h

|

2100*1200*1890 mm

|

900 kg

|

|

6YL-120A

|

15+1.1 kw

|

250 kg/h

|

220*1250*1890 mm

|

1000 kg

|

|

6YL-130A

|

18.5+1.5 kw

|

400-500 kg/h

|

2250*1450*2050 mm

|

1300 kg

|

|

Model

|

Capacity

|

Dimension

|

Weight

|

Power

|

|

6YL-130A Automatic Oil Press

|

450-500kg/h;

10-12T/24hrs

|

2250*1450*2050mm

|

1300kg

|

23.9kw

|

|

6YL-128A Automatic Oil Press

|

300-375kg/h;

7-9T/24hrs

|

2000*1400*1950mm

|

1200kg

|

20.4kw

|

|

6YL-125A/B Automatic Oil Press

|

210-300kg/h;

5-7T/24hrs

|

2100*1300*2000mm

|

950kg

|

20.4kw

|

|

2280*890*1775mm

|

1000kg

|

15+1.1kw

|

||

|

6YL-95A/B Automatic Oil Press

|

150-200kg/h;

3.5-5T/24hrs

|

1900*1300*2000mm

|

910kg

|

15.8kw

|

|

2250*890*1820mm

|

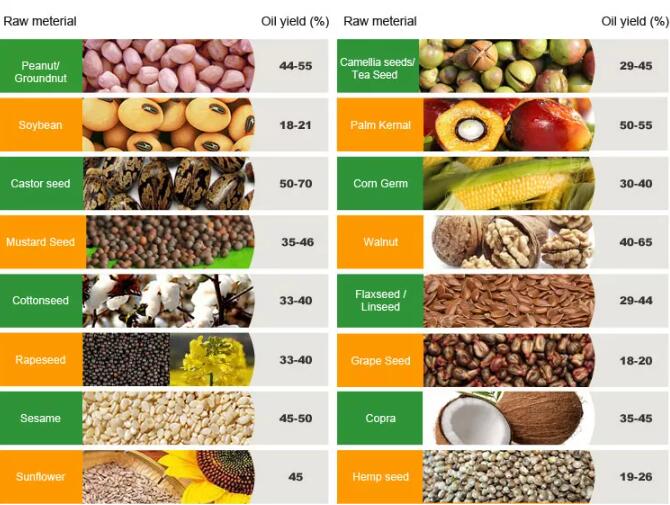

There are many different kinds of oil seeds for edible oil industry, Our Company is here to offer tailor-made oil processing solutions specifically designed according to different characteristics of different oil seeds materials.

☑ Oilseed Pretreatment: The oilseeds are procured, cleaned, flaked and cooked to ensure the oilseeds in the best condition prior to pressing and extraction.