Our Machinery is a professional soybean oil extraction machinery manufacturer and supplier, with a professional R&D team and project managers, providing the turnkey solution for home use single machine soybean screw oil press and Soybean oil extraction machine plant. Feel free to contact us for more information about how to produce soybean oil.

Recently, a Mali customer purchased a large-scale soybean oil extraction line with a capacity greater than 30 tons per day for commercial use. His raw materials were soybeans and rapeseed, and according to the customer’s requirements, 70 tons of raw materials were needed for physical pressing, 60 tons of oil cake treatment as well as 20 tons of stainless steel degumming and 100 tons of silos. In a short period of time, Our Machinery developed an engineering solution to the customer’s satisfaction.

Large-scale Commercial Investment in Soybean Oil Production Process and Equipment

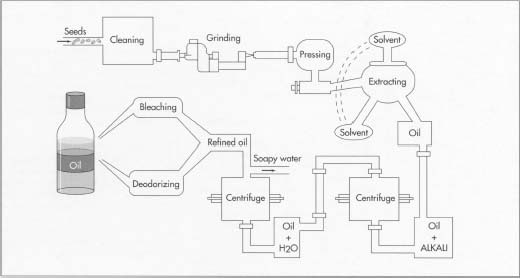

- First, collect and clean soybeans and canola raw materials. Soybeans should be cleaned using some cleaning equipment or by hand only. Since impurities may contain stones, sand, iron impurities, metal debris, etc., it is best to use a cleaning machine or sieve to remove all these impurities to better protect the soybean oil press.

- Next, the soybeans will be crushed. Soybeans are best crushed into small particles with a professional crusher to facilitate processing.

- There are two types of separation, and we usually use a soybean crushing and separating machine.

- Fourth, pressing the embryo. Before pressing, soybeans should be cooked or heated to obtain a higher quality oil and cake. The pre-treated material is then fed into the soybean press. The process of oil cake processing: cooling → crushing → automatic weighing and packing

The final refinement yields pure soybean oil. The process of degumming: gross oil → hydration degumming → oil-water separation → vacuum drying → precision filtration → finished oil. The pressed gross soybean oil should be refined through a soybean oil refinery to obtain pure edible oil.

Learn how to make multi-purpose soybean oil at low cost by soybean oil extraction machine manufacturers or suppliers at factory prices in Ghana, Zambia, Kenya, Uganda, Mali and other soybean oil extraction machine projects.

Soybean oil processing usually strat from soybean seed oil preparation. The soybeans need to be cleaned, dried and dehulled before sending to the next extraction process. The soybean hulls needs to be removed because they absorb oil and give a lower yield. This de-hulling is done by cracking the soybeans and a mechanical separation of the hulls and cracked soybeans. Magnets are used to separate any iron from the soybeans. The soybeans are also need to be heated to about 75°C to coagulate the soy proteins to make the extraction process much easier.

In the soybean oil processing, you usually should cut the soybeans into flakes and then put them in a percolation extractors and immerged with a solvent. After removing the hexane, the extracted flakes only contain about 1% of soybean oil and is used as livestock meal or to produce food products such as soy protein. The hexane is separated from the soybean oil in evaporators. The evaporated hexane is recovered and returned to the extraction process. The hexane free crude soybean oil is then further refined.

Oil refining is another important process in soybean oil processing. The oil obtained from pressing or solvent extraction process always contains impurities such as phospholipids, FFA, pigment, off-flavor and other impurities. In order to make the oil edible, the impurities must be taken out; such a process is called “Oil Refining”. The oil-insoluble material are removed with filtration and the soluble materials is removed with different processes including degumming (removing of phosphatides), alkali refining (washing with alkaline solution to remove free fatty acids, colorants, insoluble matter and gums) and bleaching (with activated earth or activated carbon to remove colour and other impurities.

Soybean oil is an edible oil with a light and clean flavor that is commonly used for cooking. The oil is 60% polyunsaturated fat and 24% monounsaturated fat, according to the National Soybean Research Laboratory, making it a heart-healthy oil.

Soybean oil is extracted by several methods. Commercially, chemical extraction using hexane is common, with this method, the oil yield is typically aroud 19% (the dreg oil in meal is about 1%). Another method is mechanical pressing, with this method, however, the oil yield is always around 13% (the dreg oil in cake is about 7%). cold pressing the beans using a small hand operated seed oil press is the most available method for extracting the virgin soybean oil at home.

Our soybean oil processing plant are designed and manufactured with advanced oil processing technology and the oil processing machinery are all of good quality. We guarantee the great service and most competitive price! Welcome to contact us, we are always at your service!