Coconut oil extraction frequently asked questions are as follows:

How is the profit of coconut oil making business?

How to select a suitable coconut oil production equipment for starting a business?

How to choose the coconut oil factory site? What are the oil extraction methods suitable for?

What cost to start a small scale or large scale coconut oil manufacturing business?

How to Start a Coconut Oil Pressing Business Plan?

When starting a coconut oil business or setting up a cattle feed processing plant, you have to make a complete business plan, make customized feed mill layout design. You should also study your customers – the edible oil varieties they keep and the market trend. We are a professional manufacturer and supplier of edible oil, you can contact us for more information.

-

Select the Best Location and Setup the Coconut Oil Pressing Factory

You may need to find some professional workers to set up the necessary infrastructure and install the processing machines. In most cases, the coconut oil processing machine supplier or manufacturer will have engineers to help you design the factory layout, install and debug the equipment.

-

Learn the Coconut Oil Production Processing Technology

Most of the coconut oil we consume in our daily life is extracted from the oil press, the water content of 10-12% of the dried coconut through the magnetic chamber to remove the broken iron, grinding fine into particles of about 0.3cm in diameter, the particles will be pressed into thin slices to expand the area of dried coconut so as to press the oil.

Related Post: Large scale high yield cooking oil production machine tanzania

Features of Small Coconut Oil Pressing Mill Complete Set of Equipment:

- The complete set of 1-5 TPD small scale pressed coconut oil mill comprehensively optimizes the working structure of each part to ensure and improve various economic indicators of the coconut oil products produced.

- This machine adopts a reasonable and practical eidble oil extraction system, which completes the whole process of feeding, converying, extraction and screening at one time. It has a high degree of automation and reduces the labor intensity of the operator.

- The machine is compact in structure, easy to operate, easy to learn and easy to maintain.

As a Coconut Oil Processing Machinery, we provide turnkey projects including special design, installation instructions, commissioning and training of workers. Our products are exported to Nigeria, Moldavia, Brazial, Jamaica,Ghana, Tanzania, Senegal etc. and other countries. If you are interested in starting a home use coocnut oil production business at a lower cost, do not hesitate to contact us, our team of engineers will customize a turnkey solution for you!

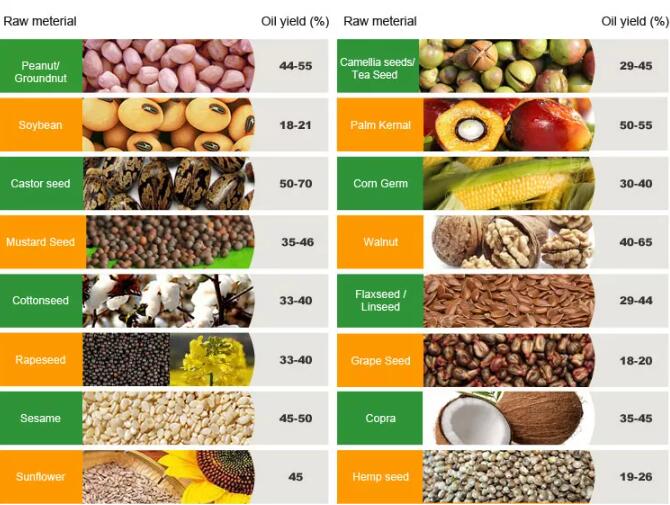

Raw material

Structure of Oil Press

Selecting the oil seed.

Before the oil into the press should be dried, clean, so that its moisture is not more than 12%, impurities are not more than 0.5%, without selection or poor selection of oil, dust will block the oil road, sand will speed up the wear of parts, not only to the normal work of the oil press has an impact, but also greatly shorten the press screw, press shaft, round row, cake mouth service life.

Frying oil seeds.

Although the screw oil press can be used for cold pressing, but the productivity and oil volume of hot pressing are higher than cold pressing.When the oil is baked and fried, the energy should be moderate and the stirring should be uniform to prevent the frying the outside of oil seeds.

Pressing oil seed.

When the press is running, the processed oil seeds enters the press chamber from the hopper.The press screw turns to push the material into the inside continuously, to press. As the diameter of the screw is gradually thickened, the pitch is gradually reduced, so when the screw is rotating, the thread is hard, the material is squeezed by the screw and the round row.To cause the oil in the oil seeds to be squeezed out and to flow out of the slot in the circular row.

Filtering crude oil.

The plate and frame oil filter machine is a pressure operated filtration device that operates intermittently. Suitable for solid and liquid separation of various suspensions. The filter chamber is composed of a filter plate. Under the action of the feed pump, the suspension (liquid material) is pressed into each filter chamber, and the solid medium and the liquid are separated by using a filter medium such as a filter cloth.

Refining oil.

The oil refine machine involves removal of the bitterness, color and odor. First the oil is heated at temperatures between 40℃and 85℃. Then it’s mixed with an alkaline substance like sodium carbonate or sodium hydroxide. The oils are degummed by treating them with heated water at temperatures between 85℃and 95℃ or with acidified water. This precipitates out most of the gums usually phosphatides. Then centrifugation is done to remove the dregs.

Parameters of Oil Press

|

Machine

|

Capacity

|

Power

|

Weight

|

Outline Dimension

|

|

Electric cooker

|

300kg/h

|

2.6kw

|

520kg

|

1800x1100x1500(mm)

|

|

Oil Press

|

500kg/h

|

18.5kw

|

760kg

|

1980x680x1460(mm)

|

|

Oil Filter

|

200-250kg/h

|

1.1kw

|

500kg

|

1200x660x910(mm)

|

|

Oil Refinery

|

200-250kg/h

|

7.5kw

|

500kg

|

2000x1000x1300(mm)

|

|

Screw conveyor

|

500kg/h

|

4kw

|

280kg

|

900x410x750(mm)

|